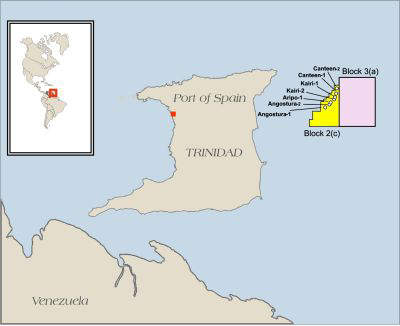

The Greater Angostura field is located in 36-46m of water on the continental shelf, 37km east of the Republic of Trinidad and Tobago in the eastern (Trinidadian) sector of the Eastern Venezuela Basin.

The shallow water integrated oil and gas field development is part of Trinidad Offshore block 2c. It is operated by BHP Billiton (45%) on behalf of joint venture (JV) partners Talisman (25%) and Total (30%). The group signed a production sharing contract on 22 April 1996 and acquired a 3D seismic survey in 1997. The JV partners will operate the field until 2021 under a production sharing contract with the country. The Greater Angostura field has a production life expectancy of 19-24 years.

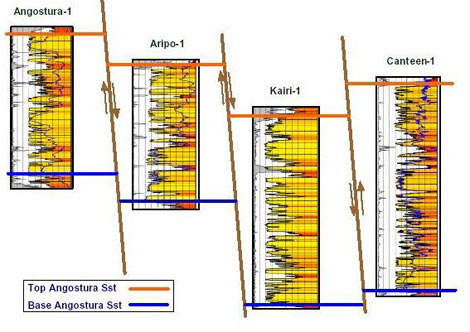

The discovery well, Angostura-1, was drilled in 1999. This intersected 950ft (gross) of gas pay. The hydrocarbon potential of the structure was confirmed by the drilling of Aripo-1, Kairi-1, Canteen-1, Kairi-2, Angostura-2 and Canteen-2 wells. Each of these exploration / appraisal wells also intersected sands. The Kairi and Canteen fault blocks contain most of the oil while Aripo has a thin oil rim overlain by a significant gas cap.

During the six-year exploration phase of the PSC a total of four exploration and three appraisal wells were drilled, discovering significant oil and gas resources within a large faulted structure known as the Greater Angostura Structure. A second 3D seismic survey was acquired in late 2001 to better image the target reservoir, refine the oil in place and derive locations for development drilling.

New contracts for Greater Angostura

In September 2008 the company entered into a contract with National Gas Company of Trinidad and Tobago (NCG) for the purchase of gas from the second phase of the Greater Angostura field.

In the same period BHP Billiton announced that the phase II development of greater Angostura would involve investment of $400m by BHP Billiton and its partners. The development includes construction and installation of a new gas export platform alongside the company’s existing facilities within the Greater Angostura field.

The facility is scheduled to go online in the first half of 2011 and will have a designed capacity of 280 million cubic feet per day.

In January 2009, BHP Billiton awarded a contract to J Ray McDermott International for the construction of a gas export platform for the Trinidad 2c field. The scope of work includes construction of a 4,000t integrated topside platform, 1,000t of piles and an 800t four-legged jacket. The gas platform will then be linked to the existing oil facilities.

In January 2010 BHP Billiton awarded a contract to DSI, a business of Wood Group, to provide commissioning services for the gas export platform.

The facility is scheduled to go online in the first half of 2011 and will have a designed capacity of 280 million cubic feet per day.

The contract for fabrication, transportation and installation of flowline (pipe laid on the seabed for transport of production or injection fluids), and transportation and installation of an umbilical (an assembly of steel tubes and / or thermoplastic hoses) for phase II of the Angostura gas project was awarded to Technip in May 2009.

Technip will weld the flowline at the group’s spoolbase in Evanton, Scotland. The offshore installation by Technip is expected to take place in 2010, using the Apache pipelay vessel.

Greater Angostura reserves

The Greater Angostura field came onstream in January 2005. This was preceded by first gas production on 16 December 2004. Gas commercialisation (phase II) will commence in 2011, depending on reservoir performance.

The gross recoverable oil reserves are estimated between 90 million and 300 million stock tank barrels, with a mid case or P50 volumes of 160 million stb.

The range of gross recoverable gas volumes is one trillion to 2.3 trillion cubic feet, with a mid-case volume of 1.75 trillion cubic feet. On an oil equivalence basis, the mid-case resource is estimated at approximately 450 million barrels of oil equivalent.

Development concept phase I

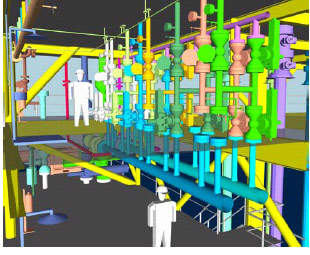

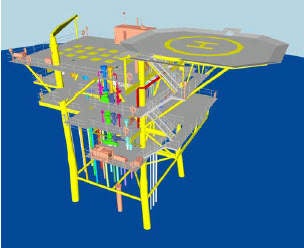

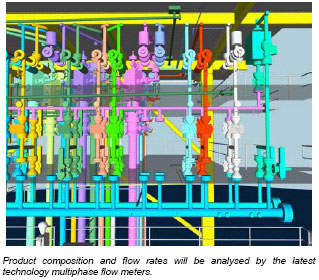

In the first phase of the development oil is produced from three wellhead protector platforms (WPP) via flowlines to a steel jacket central production platform (CPP). The front end engineering design was carried out by Icon Engineering in Australia.

The CPP topsides were fabricated, integrated and loaded onto the transportation barge Ocean Seal by Gulf Marine Fabricators in Corpus Christi, Texas, US. The bridge and flare boom were successfully fabricated by TOFCO in Trinidad, and loaded out at La Brea onto cargo barge CMS-1264. The fabrication of these components follows the earlier successful fabrication of the K1 deck in Trinidad.

The topsides comprise five main decks – the cellar deck, production deck, mezzanine deck, main deck and compression module upper deck. The upper deck of compression module lies 137ft above sea level and the tip of the flare boom stands 198ft above sea level.

The CPP weighs 7,156t and measures 215ft by 160ft by 164ft high. The topsides sit on an eight-legged jacket, measuring 135ft by 60ft at the top and 157ft by 82ft at the base.

The jacket, which stands in 110.5ft of water and weighs 1,779t, was secured by 2,223t of piles. The jacket was fabricated by Gulf Island Fabricators in Houma, Louisiana, and transported 2,100 nautical miles in 15 days from Houma on Crowley Barge 410.

The oil is transported via an 18in pipeline from the CPP to an onshore storage and marine loading facility located at Guayaguayare Bay for export to market. Gas commercialisation (phase II) will begin in 2011. Stolt Offshore was the contractor for the 80km pipeline installation and the mooring system was provided by Bluewater Energy.

Produced gas is treated to recover liquids, then reinjected to maintain reservoir pressure and enhance oil recovery. The central production facility has a capacity to process 100,000 barrels of oil per day. All production facilities are of conventional design.