BMT and Sonardyne have been selected by Sofec to supply a new mooring monitoring system (MMS) for a deepwater development, offshore Mozambique.

The system will involve monitoring of the turret mooring system on a new-build floating liquefied natural gas (FLNG) facility which is being built in South Korea for Eni’s Coral South project located offshore Mozambique.

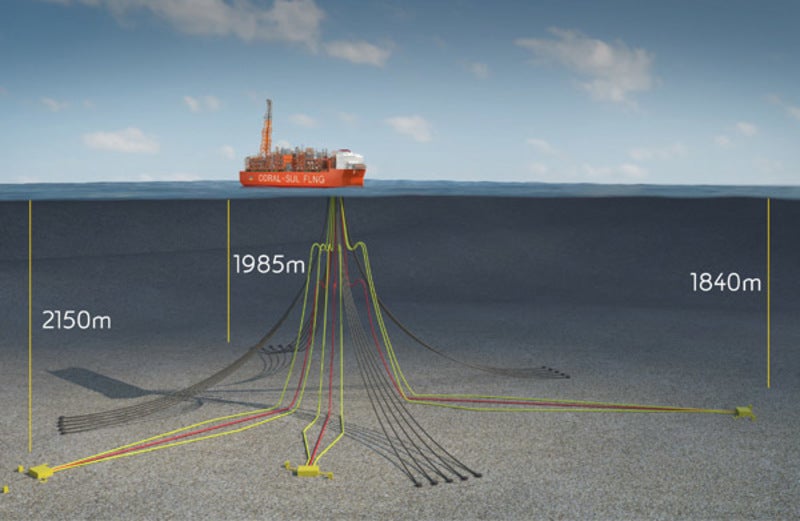

Sofec aimed to integrate a MMS with water depths ranging from 1,500m-2,300m, to complement its turret mooring solution. The company plans to use the combined engineering strength of BMT and Sonardyne to acquire the technically competent MMS.

Sofec selected the companies based on high data availability, ease of remote operated vehicle (ROV) installation, subsea technology robustness and longevity between maintenance periods offered by the system.

Sonardyne Subsea Asset Monitoring global business manager Stephen Auld said: “For this project, we’ve also increased the time between battery replacement to in excess of six years, so it’s a long-life, easy to use system to ensure integrity data acquisition.”

BMT will supply the station-keeping turret monitoring system and local control panel with touchscreen interface, on top of the waterline.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataIn order to reduce the system’s footprint, the control panel will also house Sonardyne’s topside equipment. Using the system, Sofec’s client will be able to gain remote data access through BMT’s secure Cloud-based portal, BMT DEEP.

Under the waterline, Sonardyne’s Subsea Monitoring, Analysis and Reporting Technology (SMART) will be used for constant monitoring of mooring integrity on each of the 20 anchor legs. The surface will receive daily summary reports and automatic fault detections wirelessly from the SMARTs real-time.