Aker Solutions has secured a contract from TotalEnergies to provide deepwater subsea production systems (SPS) for a field off-coast the Republic of the Congo.

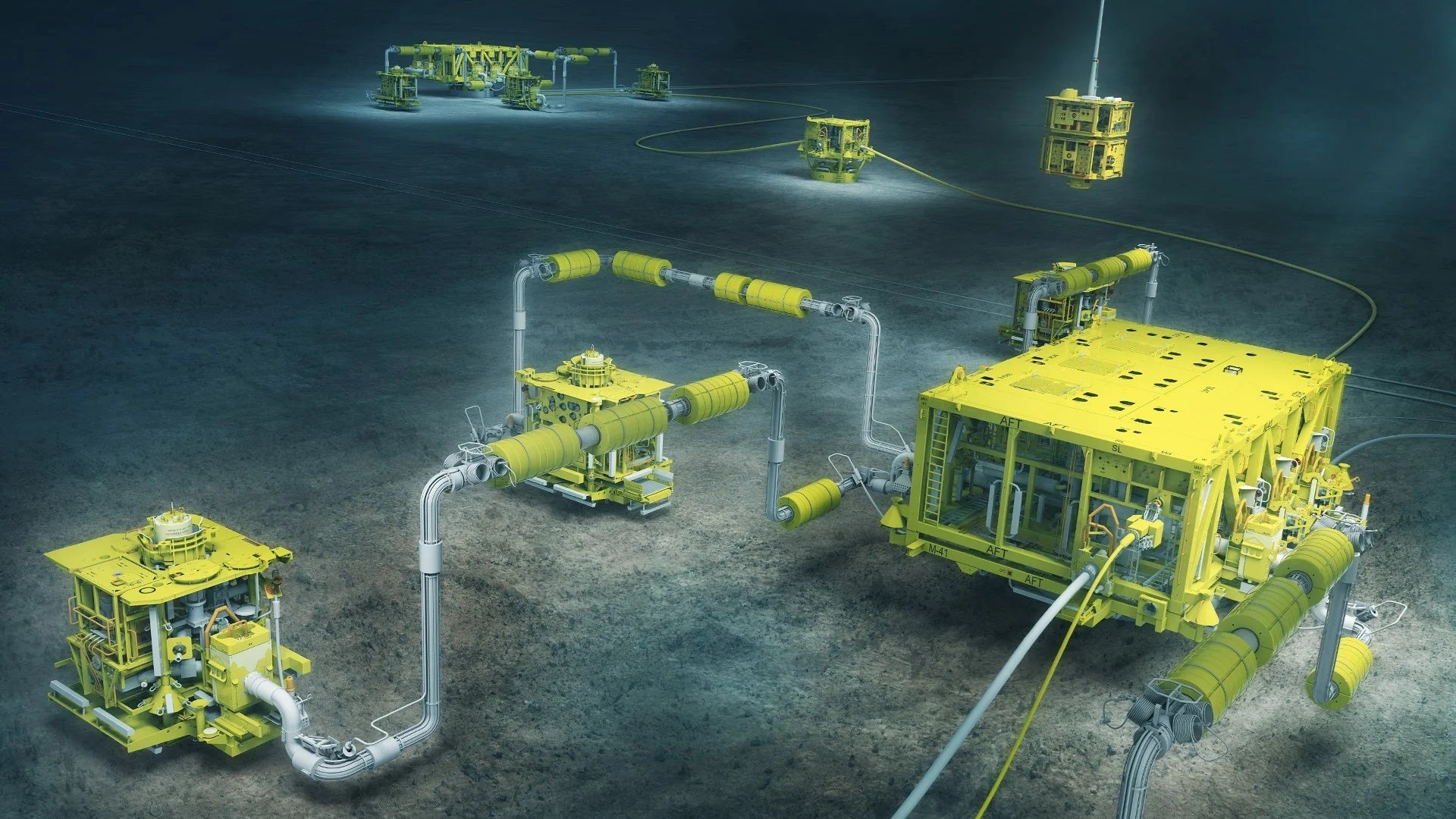

Under the contract, the Norway-based offshore engineering company will provide its standard and configurable SPS for three additional infill wells tied back to the Moho Nord field.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The SPS will include subsea x-mas’ trees, control systems, wellheads and related tie-ins and distribution infrastructure.

Aker said the operation began right away and the final delivery is scheduled for the first quarter of 2025.

It defined the contract as sizeable, and valued between around $47m and more than $140m.

Deep offshore oil project Moho Nord is located 75km from the coast of Congo at depths ranging from 750m to 1,200m.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIt began production in March 2017 and is currently the biggest oil project ever developed in the country, representing more than half of its oil production.

The field is operated by TotalEnergies, which has a 53.5% stake in it.

Chevron and Société Nationale des Pétroles du Congo are partners in the project, controlling 31.5% and 15% stakes, respectively.

Aker Solutions executive vice-president and head of subsea business Maria Peralta said: “We are pleased to continue our long-standing relationship with TotalEnergies. For Moho Infills, we will deliver TEP Congo with the deepwater version of our standard and configurable SPS technology, leveraging our unique success with standardisation and industrialisation.

“This standardised deepwater technology combines several advantages for the operators, including shorter lead times, more flexibility and increased competitiveness – the essence of standardisation – and a reduced carbon footprint, thanks to its design.”