At this point it is clear that the oil and gas industry’s labour deficit is a problem for today, not tomorrow. According to research by PricewaterhouseCoopers, the industry needs to find 120,000 new employees over the next 10 years to avoid a disruptive skills shortage, and the effects of that need are being felt today.

“The amount of jobs up here – it’s scary to be honest,” said Mark Mallin, a new hire in Aberdeen’s offshore oil and gas industry, in an interview with The Telegraph in September 2013.

“If you go on to one of the careers websites there are literally hundreds if not a couple of thousand jobs every day…companies ask for an experienced guy but a lot of the experienced guys are retiring or coming onshore to work so they need to widen it up a bit. They have got to think outside the box.”

Expertise efficiency: the lure of the digital oil field

One of the ways O&G majors are beginning to think outside the box is the increasingly advanced implementation of the so-called digital oil field (DOF). This is a broad term covering the use of connected technologies and big data innovations to optimise E&P operations and allow for remote monitoring and decision-making support.

These technologies are also seen as a good way to make the most of experienced employees’ expertise, as the ability to monitor and support multiple wells simultaneously using streamlined, real-time data is far more time-efficient – not to mention safer – than travelling out to individual operations, which are often located in remote offshore environments.

If deployed properly, DOF innovations have proven themselves effective savers of cost and time for offshore O&G projects and a boost for broader company performance. Chevron, which has emerged as one of Big Oil’s leaders in DOF technology, reports that its original DOF initiative, dubbed i-field, has unlocked hundreds of millions of dollars in cost savings and improved output since 2002, and the company’s introduction of a remote machinery support centre (MSC) and real-time drilling optimisation centre (RDOC) at its Houston offices has been paying dividends.

Safety is an operational imperative but what about the more subtle health effects of the offshore lifestyle?

The MSC, for example, was recently able to spot a compressor in danger of overloading before the on-site crew at Chevron’s Sanha field offshore Angola.

“The crew acted on the MSC’s tip and avoided a couple of million dollars in downtime and lost production,” said Chevron Energy Technology Co.’s machinery and electrical power system manager Fred Schleich.

The hybrid engineer

But actually realising the benefits of DOF technologies isn’t as simple as setting up a wireless sensor network and pushing the ‘on’ button. The level of data management and analytics required for successful DOF deployment is still unfamiliar territory for large sections of the industry – especially veteran engineers more accustomed to hard graft than smart tech and the Internet of Things – so the human factor can be a significant pitfall.

This was noted in a 2013 Geo ExPro article by Dr Julian Pickering and Samit Sengupta, whose respective companies Digital Oilfield Solutions and Geologix have partnered to provide DOF training services to the industry through a company called Digital Oilfield Training Services (DOTS).

“[DOF] projects can fail due to a lack of project preparation and a failure to understand the magnitude of the task to transform a company focused on more traditional operations,” Pickering and Sengupta wrote. “It is easy to launch into significant technology deployment projects without recognising the risks or potential value in advance, and this can cause a number of challenges to the team; indeed, in the worst case scenario, operational performance may actually decrease.”

It’s clear, then, that as well as technical change, DOF implementation requires a shift change in terms of human resources as well. The oil and gas industry has been set up to create engineering specialists for decades, but the demands of the digital oil field place a higher value on a broader skill set, the ideal employee combining a working knowledge of offshore technical issues with digital know-how.

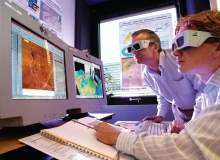

“What we increasingly need are hybrid engineers, people who are competent in key technical issues as well as digital processes like data mining systems, artificial intelligence and immersive visualisation,” said Dr Iraj Ershaghi, director of the petroleum engineering programme at the University of Southern California (USC) in an interview with Oil & Gas Agenda. “I think when you merge them together you get a very interesting interplay.”

Learning new skills

Providing training and support to workers as DOF continues to shift the industry’s skills landscape can be more important for a project than the technical aspects, according to a piece written by Chevron solution architect Amol Bakshi for the Institute of Electrical and Electronics Engineers.

“The portfolio of digital oilfield projects pursued to date has many examples of systems and solutions that could be considered successful from the purely IT perspective, but have little or no usage among the targeted end users because stakeholder engagement, communication and training activities were not adequate,” wrote Bakshi.

Beyond internal training and thorough communication to get the most out of DOF projects through employee skill development, courses are now starting to crop up to help familiarise offshore engineers and other staff with digital technologies and the communications skills necessary to find success in the DOF space.

The aforementioned DOTS provides training services and runs industry courses to this end, bringing together concepts like IT architecture design, adapting workflows to DOF systems, well planning and employee engagement.

Materials for a recent two-day DOF course make it clear, again, that broad knowledge of a wide range of skills and the ways in which they intersect holds more value than specialised expertise in a single field: “Few people can claim to be experts in all of these disciplines, but the digital oilfield project manager or coach must have a working knowledge of all of them and understand the essential role that each has to play in a successful implementation.”

Engaging new talent

Universities also have an important role to play in the development of digital skills in the offshore workforce, but for the most part the onus remains on the industry to collaborate with academic centres to put together courses and curricula that reflect the growing prominence of IT and wireless technologies.

Improved mathematical modelling and analysis is beginning to overcome many of the shortcomings of weather prediction.

Again, Chevron has pushed to the head of the pack in this regard, leveraging its longstanding relationship with USC’s Viterbi School of Engineering to sponsor the establishment of the Center for Interactive Smart Oilfield Technologies (CiSoft), which offers a Master’s degree and a graduate certificate course in Smart Oilfield Technologies.

Of course, simply enhancing the skill set of an existing workforce that is on the brink of retirement is not going to be enough. One of the industry’s toughest challenges is to persuade young recent graduates that the offshore oil and gas sector has something to offer them.

In this sense, the rise of the digital oil field could become a key selling point for the millennial generation that has grown up with digital technologies. As well as offering the benefit of a much more stable onshore place of work, the data analytics and IT innovations involved in DOF might prove a more compelling hook than the heavy engineering and anti-social hours of traditional offshore work.

“The lure of seeing how these advanced technologies work and how sites can be managed is very attractive,” Ershaghi told Oil & Gas Agenda. “This is the gaming generation, and in this job you get to play games with an entire oilfield.”

The digital oil field does provide a potentially game-changing avenue for offshore oil and gas operators to both maximise project productivity and help address the looming labour crisis through more efficient workflows.

Nevertheless, while the technology to support the growing deployment of DOF innovations has been proven, the challenges involved in fostering these new skills in the workforce mean it will not be an easy ride unless companies are willing to invest in the human side of the digital revolution.

.gif)