The production and use of biodegradable, or ‘environmentally acceptable lubricants’ (EALs), by the major oil producing companies is coming to the fore as a replacement for traditional petroleum-based lubricants. This move is driven by a mixture of legislation and a growing consumer desire for greener practices and processes within one of the world’s largest industries.

A study by Persistence Market Research into the bio lubricants market expects it to grow at a combined annual growth rate of 5.2% to 2031, with revenues in excess of $2.4bn. The Asia-Pacific region is expected to be the largest market for bio lubricants, mainly driven by the growing industrial demand from countries such as China and India, while North America and Europe are also significant markets.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

With an increasing number of companies interested in developing bio lubricants, and more legislation than ever in place to codify and organise them, the future could be bright for new kinds of lubrication tools.

Regulations underpin growth

The move towards the provision of biodegradable lubricants is undoubtedly underpinned by regulation. However, it is also clear that in an environment where consumers are more aware than ever of a company’s environmental footprint, oil companies are keen to demonstrate that their products are minimising environmental damage and improving efficiency.

There are a number of regulations in place globally to govern the use of lubricants in the offshore environment. In US waters, the Environmental Protection Agency (EPA) regulations mandate the oils and lubricants that can be used.

“Marine lubricants in US waters are subject to the EPA’s Vessel General Permit (VGP) regulation,” explains John Fang, staff scientist at Chevron Lubricants. “The VGP standard requires that any lubricant used in oil-to-sea interfaces – in other words, likely to come in contact with water – must be an EAL.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

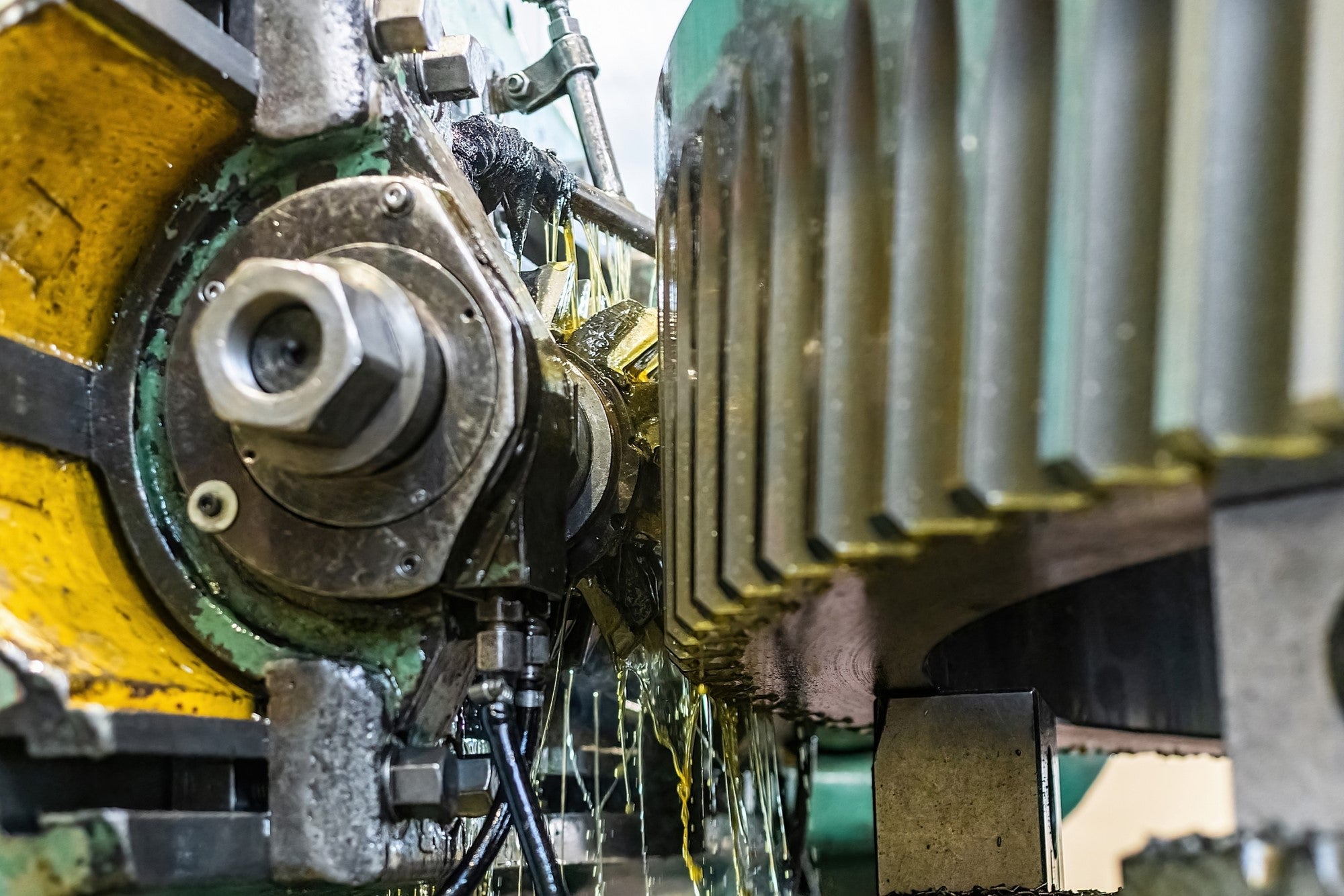

By GlobalDataFang also notes that the greatest demand for EALs is in hydraulic systems, a key component of the offshore industry, and one that has encouraged the sector to invest considerably in biodegradable lubricants. Under the VGP definition, the oil must be low in toxicity to aquatic organisms, and ‘non-bioaccumulating,’ meaning it won’t take a concentrated form inside an organism.

In the EU, the Ecolabel for Lubricants (EEL) in 2018, which is valid until 31 December 2024, is the quality guarantee label for lubricants. Oil companies can apply for the EU Ecolabel to be placed on their product as a guarantee that the lubricant will have a reduced impact on the aquatic environment and the soil during use, and is a leading form of recognition within the sector.

“The EU’s EEL requirements are the most structured, and extend across eight criteria: aquatic toxicity, excluded substance, biodegradability and bioaccumulation, packaging/container requirements, minimum technical performance, use and disposal,” Fang continues.

Avoiding greenwashing with biodegradable lubricants

Although the move towards greener lubricants is happening across the board, there are a number of confusing, and possibly misleading, terms to describe lubricants on the market.

In order to bring some semblance of order to the terminology EALs are now recognised as, “the more appropriate and standard term, based on quantifiable industry specifications for biolubricants,” said Fang. In a nutshell, EALs are those that have the ability to degrade naturally by the actions of biological organisms.

However, in order for an EAL to be classified as biodegradable it has to meet certain standards and must be distinguishable from petroleum products. EALs have to demonstrate that they are ”readily biodegradable” and can meet the ISO 9439 or OECD 301B standards.

These state that a lubricant has degraded by more than 60% within 28 days. By contrast, petroleum-based lubricants can only naturally degrade at a rate of 15%-35% in 28 days. A biodegradable lubricant must also be of ”low toxicity”, to be determined by tests involving fish and other sea life.

Keeping environmental credentials clear is important, considering some of the damage that some lubricants can cause. Polyalkylene glycols (PAGs), vegetable oil, synthetic esters, or a combination of these, are commonly used as base stocks for biodegradable lubricants, but these lubricants are incompatible with other oils.

They can also cause problems if mixed with non-PAG oils and can react poorly with seals and paints, making them potentially unsuitable for use in offshore facilities. It is for these reasons that synthetic esters that have less toxicity, and that are more biodegradable, are preferred for EALs. These can be added to vegetable-oil based lubricants to improve low temperature properties.

Industry interest

TotalEnergies has in its portfolio a range of multipurpose biodegradable lubricating fluids for both hydro turbines and hydraulic systems, specially designed for hydropower generation.

Meanwhile, Shell, through its range of ‘Naturelle’ branded lubricants, is expanding in the EAL market. At the end of last year, Shell completed its acquisition of the Environmentally Considerate Lubricants (ECLs) business of the Swiss based Panolin Group.

Shell has said that it expects to fully integrate the business into its global lubricants business, “within two years,” as both companies look to work together to better develop and expand lubricants in the sector.

Last year, Chevron Marine announced the development of an EAL for wet, corrosive conditions. Its Clarity Synthetic EA Grease 0 is based on biodegradable synthetic esters and is suitable for marine applications . These include on rudder carrier pumps, slides, hinges, and propeller caps, making it an attractive product for the oil and gas sector.

The grease is readily biodegradable and is able to be pumped within most modern, centralised lubrication systems. It contains antioxidants, corrosion inhibitors and extreme pressure and anti-wear additives. Chevron technical field specialist Martin Roessner adds, “This is an important addition to our product portfolio. Wherever the application involves a risk of contamination to the water, soil or channels, this new Clarity Synthetic EA Grease 0 is recommended.”

These initiatives are not taking place in a vacuum, however, as an increasing number of companies are seeking certification of their lubricants through bodies such as the Ecolabel. The EU claims four out of five European consumers would support purchasing products such as green lubricants, provided they are properly certified by an independent organisation.

As Merja Lämsä, R&D manager at Bionol BioSafe Oy, whose company has applied for the Ecolabel says: “Our company has reaped the benefits of its long research and development experience and proved it is possible to produce long life hydraulic fluids based on renewable raw materials.

“Our aim is to spread our know-how of long life hydraulic fluids based on renewable raw material. Our target is to provide our customers with both technical and environmental proof of the excellent behaviour of these products.”