The oil and gas industry continues to be a hotbed of patent innovation. Activity is driven by an increasing need for long-term sustainability, reducing capital and operating expenses, minimizing its carbon footprint, and transitioning towards low-emission fuels. Technological advances and growing research in the field of alternative fuels are enabling these objectives to be achieved. This is characterized by the growing importance of technologies, such as low-carbon hydrogen, liquified natural gas (LNG), and carbon capture and storage (CCS). In the last three years alone, there have been over 523,000 patents filed and granted in the oil and gas industry, according to GlobalData’s report on Innovation in oil & gas: gas storage vessel fabrication. Buy the report here.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

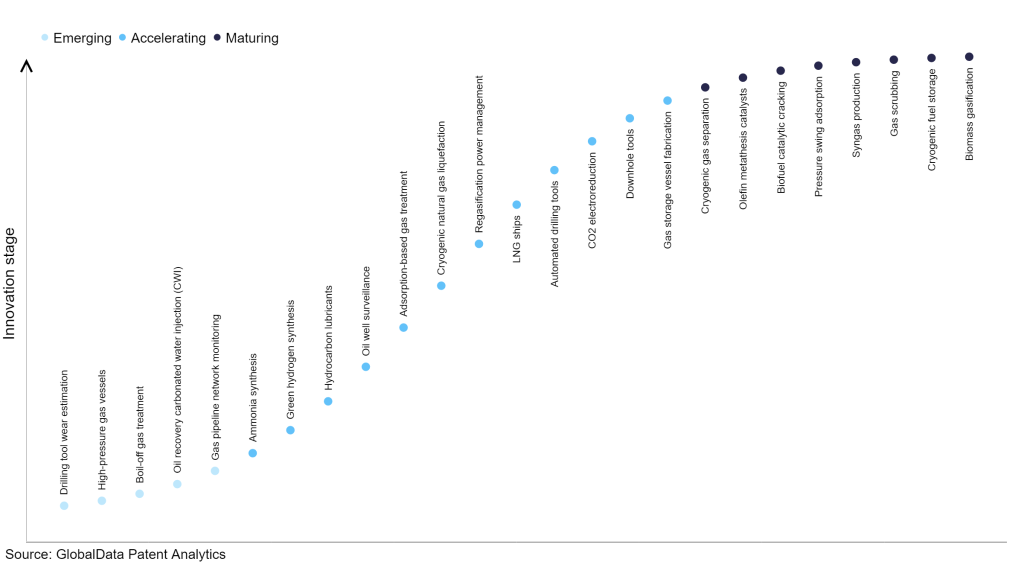

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilizing and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

60+ innovations will shape the oil & gas industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the oil & gas industry using innovation intensity models built on over 196,000 patents, there are 60+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, high-pressure gas vessels, boil-off gas treatment, and oil recovery CWI are disruptive technologies that are in the early stages of application and should be tracked closely. Green hydrogen synthesis, hydrocarbon lubricants, and oil well surveillance are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas are cryogenic gas separation and olefin metathesis catalysts, which are now well established in the industry.

Innovation S-curve for the oil & gas industry

Gas storage vessel fabrication is a key innovation area in oil & gas

A gas storage vessel is a pressurized container designed to store gas under specific conditions. There are various types of gas storage tanks, such as pressure tanks, bullet tanks, LNG storage tanks, and CNG tanks, among others. These tanks are also installed underground when there is a need to storage liquids or gases in large volumes. These tanks can be constructed from high-performance materials, including aluminum, steel, and fiberglass.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 280 companies, spanning technology vendors, established oil & gas companies, and up-and-coming start-ups engaged in the development and application of gas storage vessel fabrication.

Key players in gas storage vessel fabrication – a disruptive innovation in the oil & gas industry

‘Application diversity’ measures the number of applications identified for each patent. It broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of countries each patent is registered in. It reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Air Liquide is the top patent filer for gas storage vessel fabrication, followed by Toyota Motor and Linde. Other leading companies in the field include Engie, Honda Motor, Hexagon Composites, and Enovis.

Air Liquide is a leading producer and supplier of industrial gases and offers a range of vessels to store and transport gases, including liquified gases and cryogenic gases. Linde’s portfolio includes various types of pressure-tight vessels, such as cylinders, cylinder bundles, and tanks for storing gases either in compressed or liquified state.

Hexagon Composites has expertise in offering Type 4 composite technology in its storage cylinders, which are used in a wide range of industrial applications. The Type 4 composite technology enables in fabrication of light weight, corrosion resistant, cylinders for storing gases under high- or low-pressure conditions.

To further understand the key themes and technologies disrupting the oil & gas industry, access GlobalData’s latest thematic research report on Oil & Gas.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.