Seagull oil field is located in block 22/29C of production license P1622 in the Central North Sea, UK.

Block 22/29C is jointly owned by Neptune Energy (35%, operator), BP (50%), and JAPEX (15%). The field development plan (FDP) for Seagull was submitted to the Oil and Gas Authority of the UK Government (OGA) in March 2019 and is currently pending approval.

Development for the project is scheduled to be commenced in 2019 upon approval, while first production is expected to be achieved in 2021.

The field is expected to produce 50,000 barrels of oil equivalent per day (boepd) initially, 80% of which will be oil, over its ten-year life.

Seagull oil field location

Seagull is a high-pressure, high-temperature oil field situated 300km east of offshore Aberdeen in the UK North Sea.

It lies 17km south of the Eastern Trough Area Project (ETAP) central processing facility (CPF) and 80km south of the Forties field, which is the biggest oilfield in the UK North Sea.

Seagull oil field discovery and reserves

Seagull oil field was discovered by the 22/29-2 and 22/29-2S1 wells drilled in 1991 by Shell UK. The two wells encountered 124ft and 441ft oil columns in the Middle Jurassic Pentland and Triassic Skagerrak sands respectively.

The wells flowed at the rate of 4,350 barrels of oil per day (bopd) with 42º API oil.

The Seagull oil field is estimated to hold 50 million metric barrels of oil equivalent (Mmboe) of proven and probable reserves.

Seagull oil field appraisal details

Shell drilled the 22/29-3 appraisal well at the Seagull field in 1992, which encountered a 148ft oil column in Upper Jurassic Kimmeridge and Middle Jurassic Pentland sands, and a 239ft oil column in Triassic Skagerrak sands.

The field reservoir was considered to be of poor quality until re-examination of data in 2006 that established that the reservoir was of much higher quality.

Another appraisal well was drilled in October 2015 by Apache. The well encountered 672ft of net oil pay in Triassic-age sands. The well tested 42º API oil and flowed at a maximum rate of 1,279bopd and 841bopd from the Kimmeridge and Skagerrak sands, respectively.

The well was production-tested and flowed at the rate of 8,700bpd and 16 million metric cubic feet a day (Mmcfd).

Seagull oil field development details

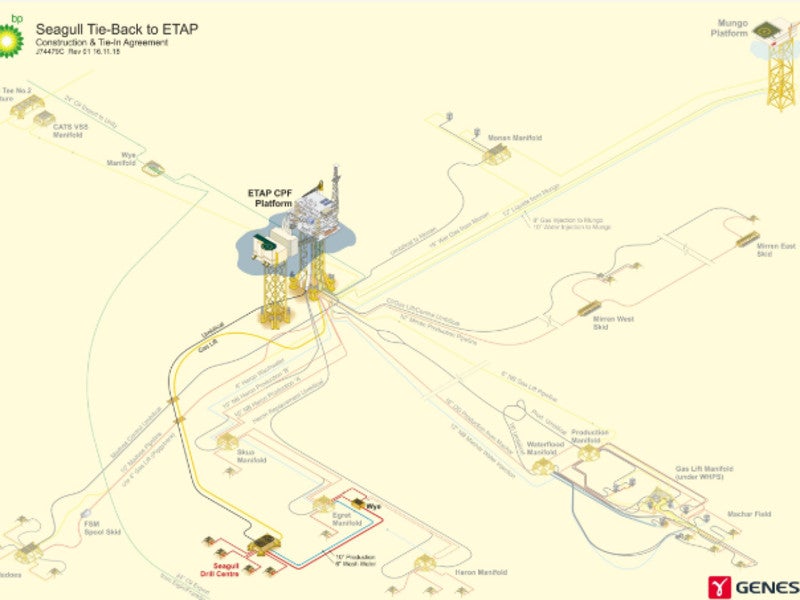

The Seagull oil field is planned to be developed through four production wells drilled from a new four-slot manifold. A 17km-long control umbilical from ETAP will be installed to the manifold.

A new 5km subsea pipeline will be installed from the field manifold to the existing Heron pipeline system through a tie-in skid at the Egret manifold for transporting the produced fluids.

The Heron pipeline system and riser will then transport the produced fluids to the ETAP CPF.

Transportation of produced oil and gas

Produced gas will be exported via the Central Area Transmission System (CATS) pipeline to the CATS processing terminal at Teesside, UK.

Produced oil will be exported via the Graben Area Export Line (GAEL) and Forties Pipeline System (FPS) to the Kinneil terminal onshore Grangemouth.

GAEL transports unstabilised oil from the ETAP, Elgin/Franklin, and Shearwater platforms to the FPS. The Forties Blend is transported to the Load Terminal, Hound Point, while raw gas is sent to the Kinneil terminal.

Contractors involved

Infinity was awarded a contract for providing subsea technical assistance and pipeline engineering services for the pre-front end engineering and design (FEED) and FEED phases of the project.

Wood Group (UK) was awarded a FEED contract for modifications to the ETAP CPF for receiving the Seagull subsea tie-back, while Xodus Group was contracted to perform subsea engineering works and concept selection.