The Cambo oilfield lies in blocks 204/9 and 204/10, approximately 125km north-west of the Shetland Islands off the shore of the UK.

It is one of the deepest fields ever to be discovered in Northern Europe and is located in 1,100m of water.

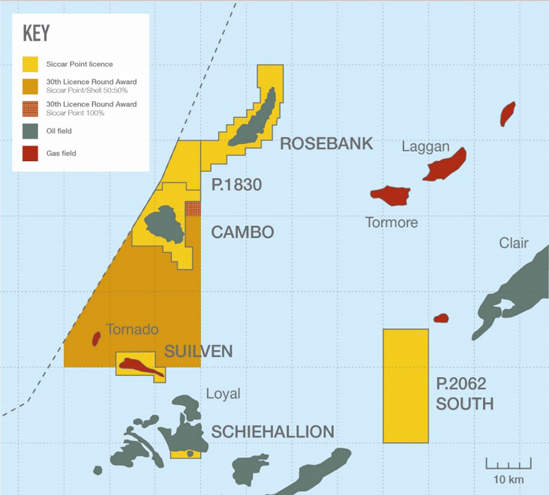

The field is situated 30km south-west of the Rosebank field and 50km north of the Schiehallion field.

The Cambo field is jointly owned by its operator Siccar Point Energy (70%) and Shell UK (30%).

Siccar Point purchased a 100% interest in the field following the acquisition of OMV UK in January 2017. Shell UK subsequently farmed into the field in May 2018.

The partners are currently evaluating development concepts for the field. The final investment decision (FID) is expected to be taken in the second half of 2021.

Cambo oilfield discovery, geology and reserves

The Cambo oilfield was discovered in 2002 by Hess.

It is a large basement high located on the Corona Ridge structure with sedimentary sequences wrapped on the top.

The field area is characterised by the presence of Palaeocene age sandstones containing 24° API oil.

The field reservoir is a high-quality Tertiary Hildasay sandstone reservoir of fluvial / deltaic origin.

It is estimated to contain more than 800 million barrels (bbl) of oil in place.

Exploration and appraisal at Cambo

A total of five appraisal wells were drilled at the Cambo field by Hess and OMV before its acquisition by Siccar Point.

The field’s final appraisal well was spud in May 2018.

The well is being drilled by the West Hercules semi-submersible drilling rig and will target the field’s main reservoir sequence, while an extended well test is also planned for the well.

Cambo oilfield development details

Siccar Point plans to develop the Cambo field in two phases.

The first phase will involve the recovery of approximately 170 million metric barrels of oil equivalent (Mmboe) of reserves through an early production system.

Cambo’s final appraisal well will provide the key details required to define the design requirements of the initial development phase.

The Normand Vision and Normand Reach construction support vessels are planned to be used to carry out offshore construction as part of phase one.

Phase two will focus on full field development, as well as the development of the greater Cambo area.

Drilling rigs and construction vessels details

The West Hercules drilling rig is planned to be used to drill the final appraisal well.

It is a 386.8ft-long, 317.3ft-wide, sixth-generation ultra-deepwater drilling rig and offers a maximum drilling depth of 35,000ft.

The rig is equipped with a drilling package comprising a 62m-tall derrick and draw works with a 50.8mm drill line.

Normand Vision is a VARD 3 06-type construction support vessel, which was specially built to carry out heavy construction work.

It is designed to carry out subsea structures, umbilicals, risers and flowlines (SURF) operations in harsh conditions.

The rig is equipped with a 3,000t carousel and a 150t vertical lay spread system.

It also features a 400t crane and launch system for remotely operated vehicles (ROVs).

The Normand Reach is a 121m-long, 23m-wide construction vessel featuring a 1,300m² deck and a 250t subsea construction crane.

The rig is designed to conduct ROV operations in high seas and is compliant with the latest environmental standards.

Contractors involved

Seadrill subsidiary North Atlantic Drilling was awarded the contract to drill the final appraisal well at the field.

The company will provide the West Hercules semi-submersible drilling rig for the drilling and testing of the appraisal well.

Baker Hughes, a subsidiary of GE, was contracted for the project’s early production phase with an option to extend to the full phase development.

The work includes the provision of well services solutions, as well as the supply and installation of subsea production equipment.

Ocean Installer was contracted by Baker Hughes and Siccar Point to carry out offshore execution works.

Sembcorp Marine Rigs & Floaters was awarded an exclusive front-end engineering and design (FEED) contract by Siccar for designing a Sevan cylindrical FPSO for the field development.

Genesis is executing the FEED work for the gas export pipeline.