The Bahr Essalam gas and condensate field is Libya’s biggest offshore production site. It is located within Block NC41 in the Mediterranean Sea, approximately 120km northwest of Tripoli, and contains 260 billion cubic meters (bcm) of gas.

The offshore gas and condensate field is owned and operated by Mellitah Oil & Gas (MOG), an equal joint venture (JV) between Eni and National Oil Corporation (NOC), a Libyan state-owned oil company.

Production started in 2005 as part of the Bahr Essalam Phase I project. The final investment decision (FID) for the second phase was completed in 2015 and phase two achieved first gas in July 2018.

After the first phase, the field produced approximately 600 million standard cubic feet a day (Mmscfd) of sales gas and approximately 30,000bbl/d of condensate. The production was increased by 400Mmscfd in the second phase, bringing the total production to 1,100Mmscfd.

Bahr Essalam gas and condensate field phase one development details

Phase one involved the development of the C Western area, which incorporates 11 subsea wells, and the C Central B area, which incorporates 15 platform wells.

Production from the C Western area is conveyed to the Sabratha process platform, located within the C Central B area, via two subsea flowlines.

Bahr Essalam gas and condensate field phase II development

Phase II primarily involves the development of the C Central A area and C East area, as well as upgrades to the Sabratha production platform.

At the C East area, ten wells are being developed through two clusters, and the subsea facilities are connected to the existing riser and J-tubes of the Sabratha platform.

The C Central A area incorporates three wells, of which one was pre-drilled. The two undrilled wells are developed through a single cluster and connect with the existing riser and J-tube of the Sabratha platform, whereas the CC09 pre-drilled well connects a dedicated in-line tee preinstalled on the existing gathering lines that connect the C Western area’s subsea facilities to the Sabratha platform.

Major facilities at the project include production pipelines, piggy-backed service lines, two subsea isolation valve (SSIV) structures and two SSIV umbilicals.

Gas production from the Bahr Essalam gas and condensate field phase two commenced via its first three production wells, while seven wells are expected to start production shortly.

Gas and condensate processing facilities

The gas produced from the field is treated on the Sabratha platform for separation and dehydration before being transported via a 36in-diameter pipeline to the onshore Mellitah plant for final treatment.

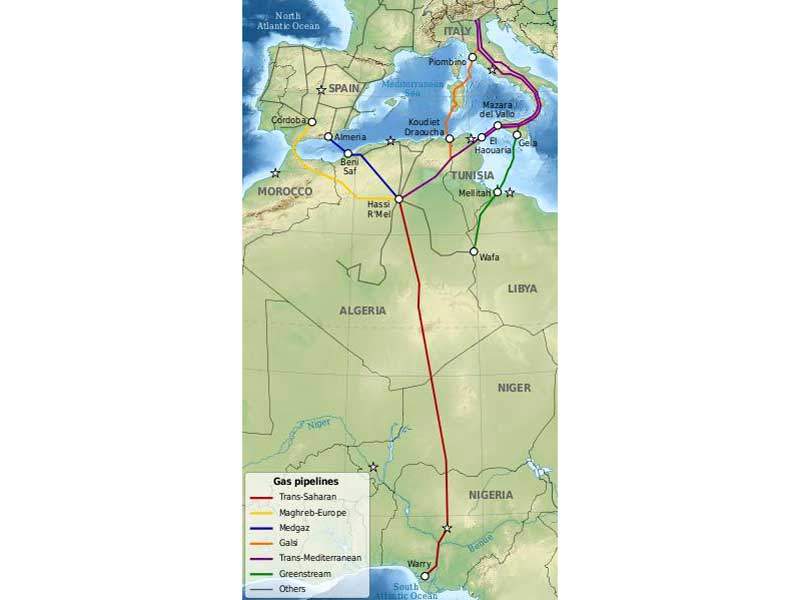

Following final treatment, the gas is supplied to the local market and exported to Italy via the Green Stream compression station and 540km-long, 32in diameter sea line.

Condensate is directly pumped and conveyed through a 10in diameter pipeline to Mellitah for further treatment and export.

The 25,000t Sabratha platform is equipped with preliminary gas separation and dehydration facilities, an 800t fast moving workover rig (FMWR), 1,800t living quarters for 117 people, a heli-deck and a 117m-long flare boom weighing 718t.

The onshore Mellitah complex is equipped with separate facilities to process oil and gas produced from the Bahr Essalam field and the onshore Wafa field. It is equipped with three trains for gas and two trains for condensate to facilitate treatment of gas and condensate conveyed from the Sabratah platform. The five trains have a dedicated capacity to treat 695MMscfd of sales gas, 31,000bbl/s of liquids and 450t of solid sulphur.

Contractors involved

In collaboration with Rosetti Marino, Saipem was the engineering, procurement, construction and commissioning (EPCM) contractor for the subsea production and transportation systems, as well as the production platform under phase one.

Maccaferri supplied its proprietary SARMAC bituminous mattress for the protection of the subsea pipelines under the first phase.

Technip was awarded a contract worth more than $500m to provide EPCM services, as well as design and pre-commissioning services for the subsea facilities under phase two. Technip deployed its Deep Energy pipelay vessel, Deep Arctic diving support vessel and G1200 S-Lay vessel to perform installation works.