Structures A and E gas fields are being developed offshore of Libya by Mellitah Oil & Gas, a 50:50 joint venture between oil and gas company Eni and the National Oil Corporation of Libya (NOC).

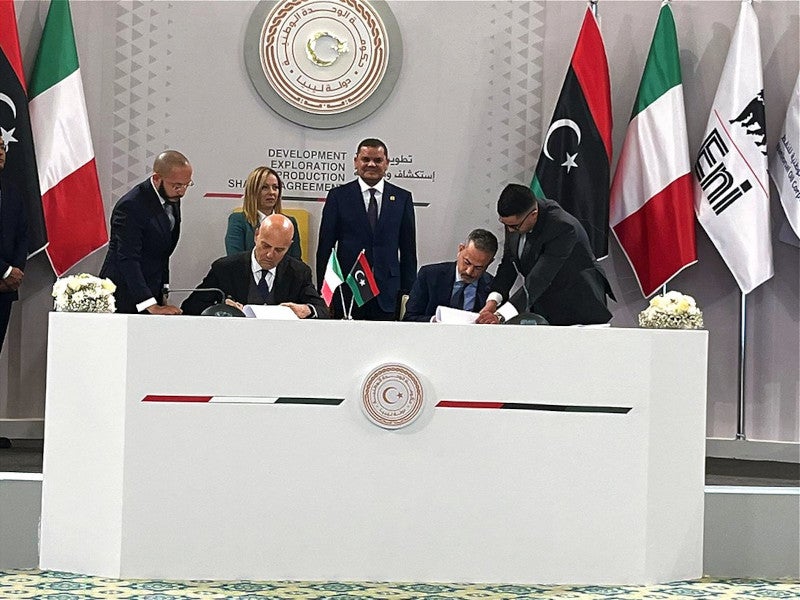

Eni and the NOC signed an agreement to develop the gas fields in January 2023. The development will require an estimated investment of $8bn and is expected to produce up to 750 million standard cubic feet of gas per day.

The project is the first major offshore development in Libya since 2000 and is expected to come onstream in 2026. It will increase gas production supply to the Libyan domestic market while also exporting gas to Europe.

Location

Structures A and E gas fields lie in Contract Area D (formerly the NC41 area), offshore Libya.

Structure A is located in the central-western part of Area D, approximately 80km off the Libyan coast, in water depths between 95m and 105m.

Structure E is located in the central-eastern part of Area D, approximately 130km from the Libyan coast in water depths between 205m and 235m.

Gas field development details of Structures A and E

The fields will be developed through two main platforms and 31 development wells consisting of subsea wet and dry tree wells.

Structure A is proposed to be developed through a dry tree/fixed wellhead platform while Structure E is proposed to be developed using an independent fixed production platform.

The Structure A platform will feature a four-legged lattice structure jacket with a pre-drilling template comprising ten well slots. It will have minimum manned facilities to accommodate approximately 20 people.

The Structure E platform will feature a 45,00 tonne (t) jacket with a lattice structure and eight legs, and topsides weighing 24,000t. The topsides will include an integrated deck with a pre-drilling template featuring 20 slots, a living quarters, and a compression module.

The first well at the Structure E field is planned to be spudded between the third and fourth quarters of 2023. A moored-type semi-submersible rig is proposed to be used for drilling the wells.

The field platforms will receive and treat the well fluid before exporting it to existing pipelines between the Sabratha platform and the Mellitah complex.

Subsea production system details

The subsea production system for the project will include five horizontal Christmas trees with multi-phase metre and related protective structures, a subsea manifold, a subsea pipeline end manifold, pipeline end terminations, umbilicals, and subsea production control systems.

A 30km-long and 36in-diameter gas pipeline will deliver production from Structure E to an existing 36in gas export pipeline from the Sabratha Platform to the Mellitah Complex. A 30km-long and 10in-diameter condensate pipeline will deliver the condensate produced from the field to an existing 10in-diameter condensate export sealine from the Sabratha Platform to the Mellitah Complex.

A new 18in-diameter multi-phase flow line from Structure A to Sabratha Platform and 16in-diameter multi-phase gathering line to tie back the subsea wells to Structure E will also be installed.

Sabratha platform details

The Sabratha platform is installed at a water depth of 190m in the Bahr Essalam gas and condensate field approximately 110km from the Libyan coast. It features a 25,000t jacket with a height of 202m and an integrated deck weighing 12,000t.

The platform is installed with facilities required for the preliminary separation and treatment of the gas and can accommodate 120 people in the living quarters that weighs 1,800t.

The Sabratha platform is planned to be modified for the development of the project. A new slug catcher separator, new risers and J-tubes will be installed. In addition, the communication systems and subsea topside equipment will be upgraded.

Processing details

The Structures A and E gas fields will be connected to the existing treatment facilities at the Mellitah complex located 22km away from Zwara City near Tripoli, Libya’s capital.

The Mellitah complex consists of two plants, one for treating the oil and condensate production from the Wafa field, and the other plant for treating the gas and condensate coming from the Sabratha offshore platform.

The complex is being expanded to handle the additional production from the gas fields. A carbon capture and storage facility will also be built to decrease the complex’s carbon footprint.

Contractors involved

PES Engineering, an Italy-based engineering, service, and project management company was selected by Eni to provide mechanical calculations and prepare mechanical data sheets for pressure vessels of the Mellitah complex.

Italy-based engineering construction consultant Tecnoconsult was contracted to provide pre-front-end engineering and design services for the pipelines and flowlines of the project’s subsea production systems. The scope of work included the design of sealines, umbilicals, expansion loop and jumpers and subsea structures.